The additional valuable components (e.g. metals) receiving from the accumulated and the current industrial products, the recycled material and the non-ferrous metallurgy industry wastes is presented itself the strategic challenge of the industry, in the context of the depletion of the primary sulfide – quality raw materials, the energy and materials costs rising for the production of metals.

Their joint melting in the blast furnace is one of the solutions, having aimed at the processing of the industrial products and the recycled materials of the lead production. So, the technology of the mine contractile melting has been established at the Ust-Kamenogorsk Metallurgical Complex LSP «Kazzink». The advantages and their disadvantages, as well as the theoretical aspects of this technology have already been presented in details in the papers [1–3].

So, it has already been established, that the observed metal redistribution towards the deterioration in the melting is closely related to the initial raw materials composition. Thus, to be achieved the high final results is virtually impossible, at the current structure of the initial raw materials.

The main aim of this work – is the theoretical estimates conducting of the metals distribution between the melting products at the optimized composition processing of the initial furnace charge of the mine contractile melting.

Materials and methods of research

The X – ray analysis of a number of the ore samples has already been carried out for the phase composition determination of the copper – zinc ore. As a result of the carried out studies, it has already been established, that Cu2S, CuFeS2, FeS and ZnS are the main components of the copper – zinc ore. The copper and iron antimonides and arsenides, as well pyrite ones have also been discovered in the ore composition. The slag components, such as – quartz and calcium oxide, in the form of the clearly defined phases, are in the free state.

At the structuring of the initial furnace charge composition, the quantitative ratios of the basic components of the initial furnace charge – the copper slips, the converter slag, and the furnace charge contractile smelting (CS), have been left quite unchanged. The optimum amount of the copper – zinc ore has been determined by the calculation, having taken into account the copper, zinc, iron, silica, and sulfur content therein, and relating to the different compounds. The metallurgical calculations of the initial furnace charge and the process material balance have already been carried out, having used the especially developed mathematical programs. The data from the factory practices and the results of the mineralogical studies on the modes of occurrence of the non – ferrous metals, arsenic and antimony in the components of the initial furnace charge and the smelting products have already been used in the calculations.

At the optimum flow of the copper–zinc ore selection, we have been assumed the integrated use possibility of the high sulfur its components (e.g. pyrite, chalcopyrite), as the sulphidation component. The thermodynamic calculations of the equilibrium interaction between the copper – zinc ore components with the slag – matte smelting components have been conducted under the «Aster» program, having used the «IVTANTHERMO» thermodynamic data base. Thus, the full potential minimization method of the Gibbs energy has been assumed, as the basis of the calculations.

The Gibbs energy interaction reactions between the oxides of the heavy non – ferrous metals, arsenic, antimony, and iron, as well as the copper and the iron intermetallic compounds (e.g. arsenides and antimonides) with the non – ferrous metals sulfides, the iron, and the high sulfur compounds of the copper – zinc ore and the products of their decomposition at the temperature 1473 and 1573 К have been already calculated. The results of the thermodynamic calculations have been confirmed the simultaneous use possibility of the high – sulfur components of the copper zinc ore, as the sulphidation component.

Results of research and their discussion

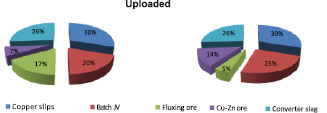

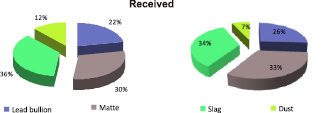

The calculated composition of the adjusted initial furnace charge of the mine contractile smelting (CS) has been presented in Figure. The comparative analysis of the material flows of the process at the processing of the existing initial furnace charge and the proposed corrected furnace charge of the new composition has been shown the significant quantitative changes of the resulted smelting products.

Ceteris paribus, at the processing of the furnace charge of the new composition it is observed the yield increase of the target products – e.g. the lead bullion and matte, up to 26 and 33 tons, respectively. This can be explained by the changes in the flow mechanism of the physical and chemical processes, having occurred in the melt. Thus, the lead bullion yield’s increase, primarily, it is explained, due to its decrease of its content in the matte. A slight increase in the matte output has been caused by the additional amount of the copper, having contributed by the copper – zinc ore, having reduced its content in the slag and the lead bullion. Reduction in the yield of the slag can be explained, in terms of the optimal selection of the slag components and the silica maximum use, having had the composition of the main components of the furnace charge. For all this, it is observed the increase in the zinc content of slag up to 12 % against 7 %, having obtained during the processing of the initial furnace charge of the existing composition in practice.

The Comparative Analysis of the Material Flows in the Processing of the Initial Furnace Charge of the Different Composition: а – the Initial Furnace Charge on the Existing Technology; b – the Adjusted Composition of the Initial Furnace Charge.

The analysis of the selected structure of the initial furnace charge has been shown, that during the furnace charge smelting of the already given composition, by the very mechanism of the process, it can be achieved the favorable conditions, having provided the poor copper and lead slag receiving. So, the preliminary calculations have already been shown, that this task will be more closed to the optimal solution, if to be impacted on the Fe–Cu–S–O system of the high-sulfur components of the copper-zinc ore before and after the slag phase formation. Thus, it is quite possible to be achieved the maximum transfer of the non – ferrous metals oxides into the sulfides, having concentrated them in the matte phase and, moreover, to be ensured the most complete impurities (e.g. Pb, As, Sb) sublimation, in the form of their volatile compounds (e.g. sulfides).

On the basis of the thermodynamic calculations, when smelting the new composition of the furnace charge, it should be expected the dissociation higher sulfide compounds of the copper-zinc ore by the following reaction:

2CuFeS2 → Cu2S + 2FeS + 1/2 S2 ↑ (1)

FeS2 → FeS + 1/2 S2 ↑ (2)

Having formed by the reaction (1) and (2), the additional amount of FeS and the excess sulfur will be reacted with the components of the slag – matte smelting, according the following reactions:

3Fe3O4 + FeS + 5SiO2 = 5 (2FeO×SiO2) + SO2 ↑ (3)

2Cu3As2 + 4,5S2 → 3Cu2S + 2As2S3 ↑ (4)

2Cu3Sb2 + 4,5S2 → 3Cu2S + 2Sb2S3 ↑ (5)

Cu2O + 2S2 → Cu2S + SO2 ↑ (6)

МеО + FeS → MeS + FeO (7)

As a result of the magnetite content reduction in the slag (3), it is provided the copper and the lead reduction in the slag. So, the progress of the reactions (4)–(7) is promoted the content increase of the sulfide copper in the matte and the favorable conditions providing for the arsenic and the antimony sublimation. Thus, the components complex use of the copper-zinc ore is allowed to be solved a number of the following objectives: the copper and the lead loss reducing with the slag on the one hand, and the obtained products quality increase, due to arsenic antimony deep sublimation, on the other hand. For all this, it is achieved the optimal distribution of the copper, lead, arsenic, and antimony between the smelting products.

The advanced process material balance during the processing of the initial furnace charge of the new composition has been given in the Table.

The Material Balance Mine Contractile Smelting Process at the Initial Furnace Charge Processing of New Composition

|

Name |

Cu |

Pb |

Zn |

Fe |

As |

Sb |

S |

SiO2 |

CaO |

Пр. |

Total: |

|||||||||||

|

Uploaded: |

||||||||||||||||||||||

|

%,т |

% |

t |

% |

t |

% |

t |

% |

t |

% |

t |

% |

t |

% |

t |

% |

t |

% |

t |

%, t |

%, t. |

||

|

CS Furn.Charge |

25 |

21,2 |

5,3 |

22,8 |

5,7 |

8,8 |

2,2 |

14,8 |

3,7 |

0,8 |

0,2 |

0,4 |

0,1 |

7,2 |

1,8 |

2,7 |

0,67 |

3 |

0,7 |

4,63 |

25 |

|

|

Cu Slips |

30 |

21 |

6,3 |

45,3 |

13,6 |

5,0 |

1,5 |

4,2 |

1,3 |

3,9 |

1,2 |

1,4 |

0,4 |

2 |

0,6 |

3,4 |

1,0 |

4,1 |

30 |

|||

|

Convect.Slag |

26 |

3,8 |

0,98 |

33,5 |

8,7 |

4,5 |

1,2 |

16 |

4,2 |

2,3 |

0,6 |

0,94 |

0,24 |

17,2 |

4,5 |

12,7 |

3,3 |

2,28 |

26 |

|||

|

Cu-Zn Ore |

14 |

2,4 |

0,34 |

0,37 |

0,1 |

3,7 |

0,52 |

26,6 |

3,72 |

31,2 |

4,4 |

15,5 |

2,2 |

14,0 |

1,96 |

0,76 |

14 |

|||||

|

Quartz Flux |

5 |

3 |

0,15 |

71,8 |

3,6 |

3,6 |

0,18 |

1,07 |

5 |

|||||||||||||

|

Average Compos.of Furn.Charge |

100 |

12,92 |

28,1 |

5,42 |

13,0 |

2,0 |

0,74 |

6,8 |

11,97 |

6,14 |

12,91 |

100 |

||||||||||

|

Received: |

||||||||||||||||||||||

|

Lead Bullion |

I |

0,3 |

24,2 |

0,03 |

0,07 |

0,01 |

1,41 |

26 |

||||||||||||||

|

II |

1,2 |

93,1 |

0,12 |

0,27 |

0,05 |

|||||||||||||||||

|

III |

2,3 |

86,1 |

1,5 |

9,5 |

0,2 |

|||||||||||||||||

|

Matte |

I |

12,27 |

3,25 |

0,67 |

4,1 |

0,27 |

0,11 |

6,18 |

1,21 |

4,94 |

33 |

|||||||||||

|

II |

37,2 |

9,85 |

2,03 |

12,42 |

0,82 |

0,33 |

18,73 |

3,66 |

||||||||||||||

|

III |

95,0 |

11,6 |

12,4 |

31,5 |

13,5 |

15,0 |

91,0 |

10,1 |

||||||||||||||

|

Slag |

I |

0,11 |

0,3 |

4,33 |

8,82 |

0,03 |

0,48 |

10,5 |

5,9 |

3,53 |

34 |

|||||||||||

|

II |

0,31 |

0,83 |

12,0 |

25,9 |

0,08 |

1,33 |

30,8 |

16,4 |

||||||||||||||

|

III |

0,8 |

1,1 |

80,0 |

67,8 |

1,5 |

7,0 |

87,7 |

96,0 |

||||||||||||||

|

Dust |

I |

0,24 |

0,37 |

0,42 |

0,08 |

1,67 |

0,56 |

0,13 |

0,26 |

0,24 |

3,03 |

7 |

||||||||||

|

II |

4,8 |

4,63 |

5,25 |

1,6 |

20,9 |

7,0 |

1,63 |

3,25 |

3,0 |

|||||||||||||

|

III |

1,9 |

1,2 |

7,6 |

0,7 |

83,5 |

75,5 |

1,8 |

2,2 |

4,0 |

|||||||||||||

|

Total: |

12,92 |

28,1 |

5,42 |

13,0 |

2,0 |

0,74 |

6,8 |

11,97 |

6,14 |

12,91 |

100 |

|||||||||||

Notes: I – amount of, t.; II – composition, %; III – distribution, %.

When the selected composition of the initial furnace, charge the technical and economic parameters of the process are being greatly increased: the copper extraction in the matte is achieved 95 %, and the lead extraction in the lead bullion is increased from 70 up to 86 %.

The Conclusions

1. It can be achieved the considerable improvement of the technical and economic indicators of the mine contractile smelting by the composition changing of the initial furnace charge.

It has also been established, that the favorable conditions are being created for the copper and the lead losses reduction with the slag and the arsenic and the antimony sublimation into the dust, at the flow increasing of the copper-zinc ore in the furnace charge.

2. The flow control and the ratio of the copper-zinc ore to the quartz flux in the initial furnace charge are allowed to be chosen the optimal value to be added to the initial furnace charge of the copper-zinc ore. For all this, the integrated use of the high-sulfur compounds of the ore, as the sulphidizer, has the fundamental significance on the metals equilibrium distribution between the smelting products.